2023-03-29

A CUSTOMER VISIT: Every year, Hjulsbro Steel imports around 30,000 mt of wire rods via the Port of Norrköping. At the beginning of the year, the company launched a new product line, the tensioning line GreenStrand™, which is made from 70% recycled steel and with only renewable energy. Now the company is expanding and building out the business with a new factory area of 2,500 square meters.

For over 100 years, Hjulsbro Steel has had its business next to the stream of Stångån in the small community of Hjulsbro just outside Linköping. A medium-sized company that has gone from manufacturing nails to making tension reinforcement to building elements that holds the Årsta bridge and Clarion Hotel in Stockholm, among others. An exciting journey continues with the new product Green Strand, made from 70% recycled steel.

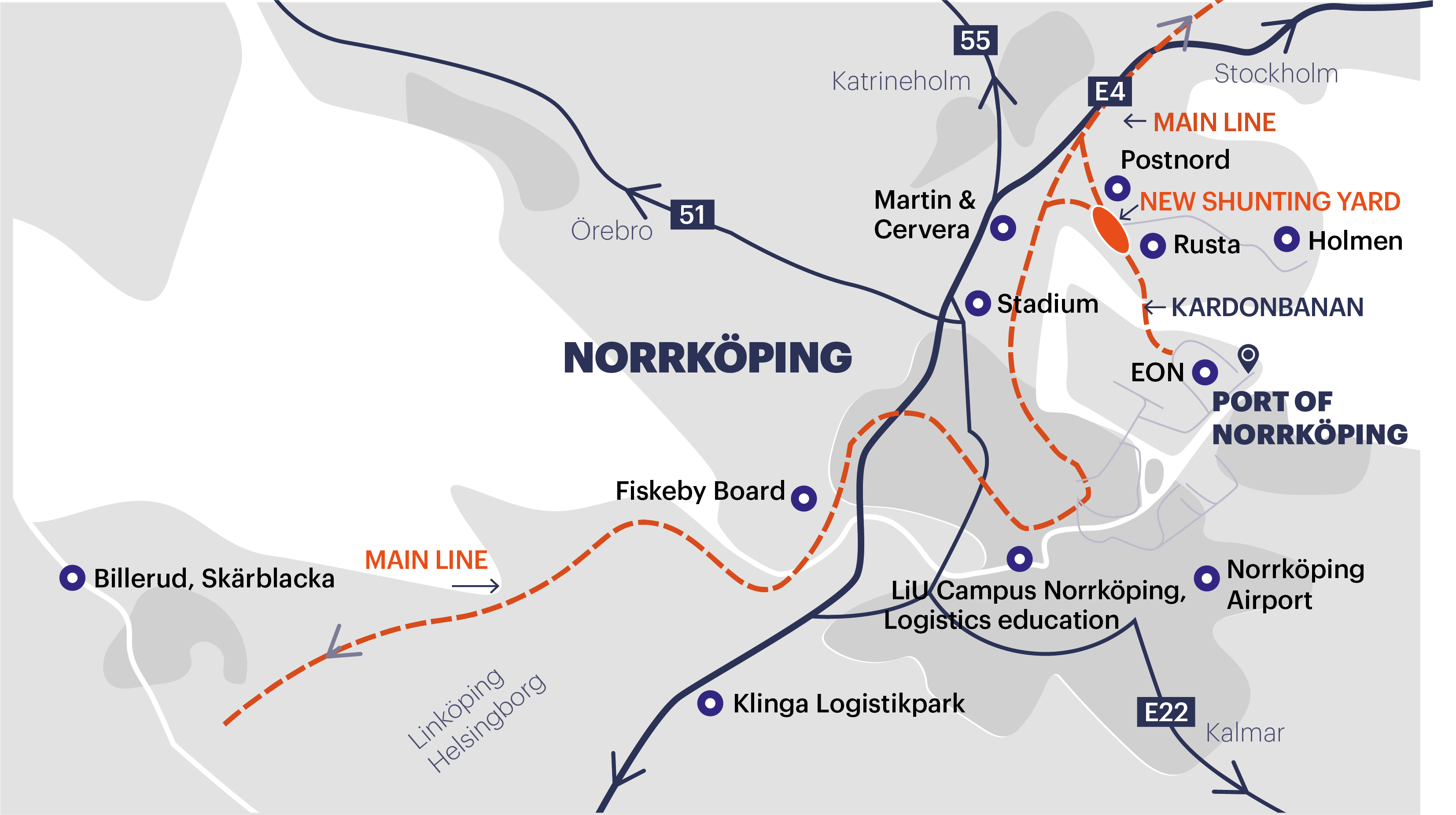

Every year, Hjulsbro Steel imports around 30,000 mt of wire rod via the Port of Norrköping. Most arrive by train from Germany and Spain via Hamburg. A large part of the wire rod is temporarily stored in the port and then unloaded by car to the factory. A small part is also exported via the port, in the last two years exports to the USA have received a boost thanks to a series of political decisions that made exporting easier.

“Two years ago we shipped maybe two containers per month to the US, last year we were up to 20 and now it’s about 30-40 containers a month year-round. We have thus doubled our exports to the US. We sell approximately 35 per cent of our products in Sweden and the rest, 65 per cent, is distributed in the Baltics, Northern Europe and the US. We also see Norway as a potentially growing customer, said the company’s CEO, Ivan Kaic, when we meet him in Hjulsbro. In the Nordics, we are the only manufacturer in our niche, our competitors are out in Europe, Ivan continued.

“We look positively on the future and our ambition is to grow the production. Right now we are in the final phase of completing an expanded factory area of 2,500 square metres where we will install a brand new production line. We also work a lot with automation to be able to be as efficient as possible in a high-cost country like Sweden.”

GreenStrand™ and the green transition

“At the beginning of January, we launched GreenStrand™, a wire strand line that is made of 70 per cent recycled steel and produced with only renewable energy. It reduces CO2 emissions by 50 per cent compared to traditional wire strand lines. GreenStrand™ meets all requirements and standards within the industry just like our traditional wire strand line. Today it is mainly sold to the railway infrastructure segment and is used in sleepers. Since rail is an environmentally friendly mode of transport, you could say that we are doubling up in sustainability”, said Ivan.

GreenStrand™

“We are part of the Linköping Initiative, a local network of companies working for a CO2-neutral Linköping 2025. Our business is very energy-intensive and through various initiatives, we have managed to reduce our electricity consumption by 5%. It may not sound like much, but seen from the perspective that we are one of Linköping’s largest electricity consumers, it is a substantial reduction. It may not be going as fast as we would like, but the whole green transition has gained momentum and we continue to work according to our sustainability strategy and energy plan. With GreenStrand™, we also show our innovative power and pursuit of sustainable solutions.

Corporate culture, inclusion and leadership

“Getting more women to work in our production would contribute positively to the business climate and we are working on it, but it is difficult to get women to apply. An inclusive workplace benefits everyone and, in collaboration with Save the Children, we have been able to offer jobs to refugees in our production. It worked very well even though the knowledge of the language was not so good at the beginning, but it progressed quickly when working with us.”

“As a manager, I am very interested in leadership and think responsiveness, clarity, courage and drive are important qualities and a certain measure of self-awareness. If I possess these qualities or not will probably show in the employee survey”, Ivan smiled.

The importance of the port for the business

“The port is incredibly important to the region and it’s important to have a progressive port with flexibility that provides the opportunity for fossil-free transport by rail or electric truck. What I think the port could do even more, is to be a link between goods owners and shipping companies and to be involved in running networks. My experience is that the Port of Norrköping is very customer-oriented in all areas, regardless of whom you are dealing with, concludes Ivan.

FACTS

Number of employees: approx. 50, production in 5-shift

Turnover(2021): approx. 500 MSEK

Customers: Mainly businesses within in the concrete industry, manufacturing prefab elements for construction and infrastructure

CEO: Ivan Kaic, born in Sarajevo, grew up in Hudiksvall. Work at Hjulsbro Steel for 10 years and CEO in four. Started as a sales manager and has a background in the steel and mining industry in Boliden, SSAB. Has a Master’s Degree in chemical engineering from Luleå University.

Hjulsbro Steels’ vision: To be the customer’s first choice and to be the most sustainable alternative

Read more: hjulsbrosteel.com